From semi-conductors to additive manufacturing, Z Prime’s AI-driven solutions enable manufacturers to optimise production processes and meet sustainability goals.

The Z Prime Solutions for Manufacturing leverage real-time monitoring, data analytics, and machine learning to optimise discrete and continuous manufacturing processes.

The use case-based solutions enable monitoring and control of production processes to identify and mitigate risk, enhance Overall Equipment Effectiveness (OEE), and optimise strategies for predictive maintenance and optimise quality.

From evidence-based decision making to unlocking circularity, Z Prime’s AI-driven solutions help water and wastewater organisations improve plant performance and resilience and meet regulatory requirements.

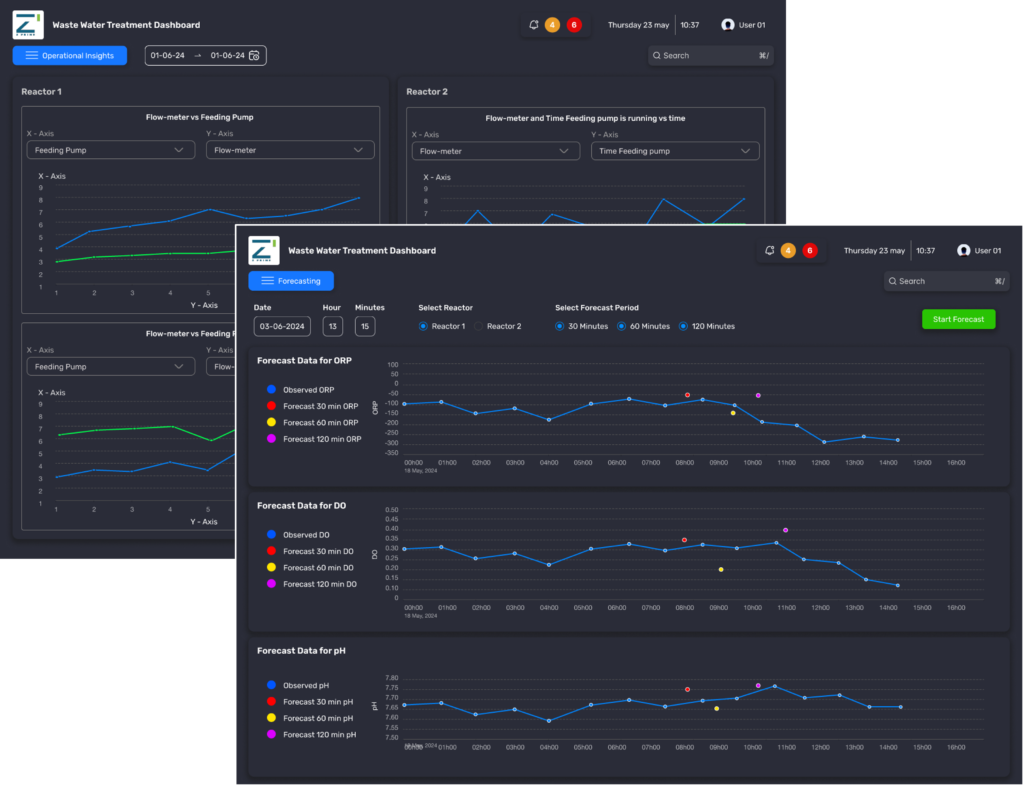

The Z Prime Solutions for Water and Wastewater industries leverage real-time monitoring, data analytics, and machine learning to optimise water and wastewater treatment processes.

The industry-specific solutions employ advanced analytics and machine learning to enable real-time monitoring of critical operational and sustainability parameters, predictive fault detection, and strategic decision-making.

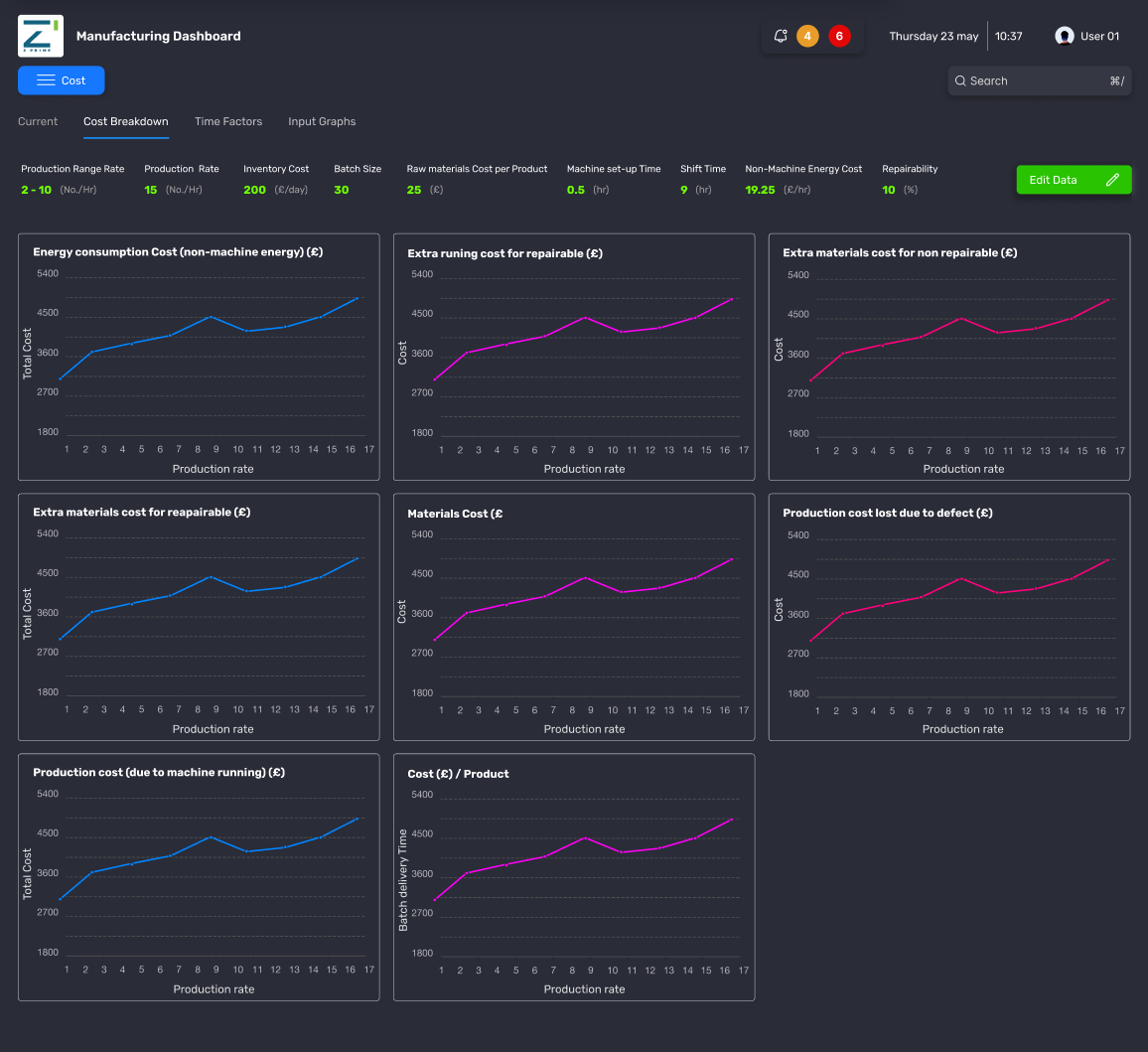

Z Prime’s unique Financial Impact solutions measure operational cost in real-time to enable key decision-makers and strategists to visualise performance against business objectives in monetary terms. Facilitating the complex transformation of engineering and operational data into financial language, Z Prime integrates sustainability and circularity goals with the cost drivers of manufacturing processes.

The Z Prime Financial Impact Dashboard Solution™ is an Embedded Cost and Risk-Based Decision Support System (CRDSS) integrating performance and maintenance KPIs into a unified cost metric.

The unique AI-driven dashboards support strategic decision-making and help companies identify inefficiencies, optimise resource allocation, and reduce production costs.

Self-service dashboards enable organisations to correlate data, highlight the sensitivity of the system to key performance parameters from multiple sources and present it in custom dashboards optimised for the business use case.

The Z Prime self-service data analytics solution can empower company experts to interpret their own data and co-optimise operational and sustainability domains without the need for data science specialists.

Powered by Z Prime’s Genomic AI Platform, self-service analytics create decision-ready information that improves reliability and operational efficiency.

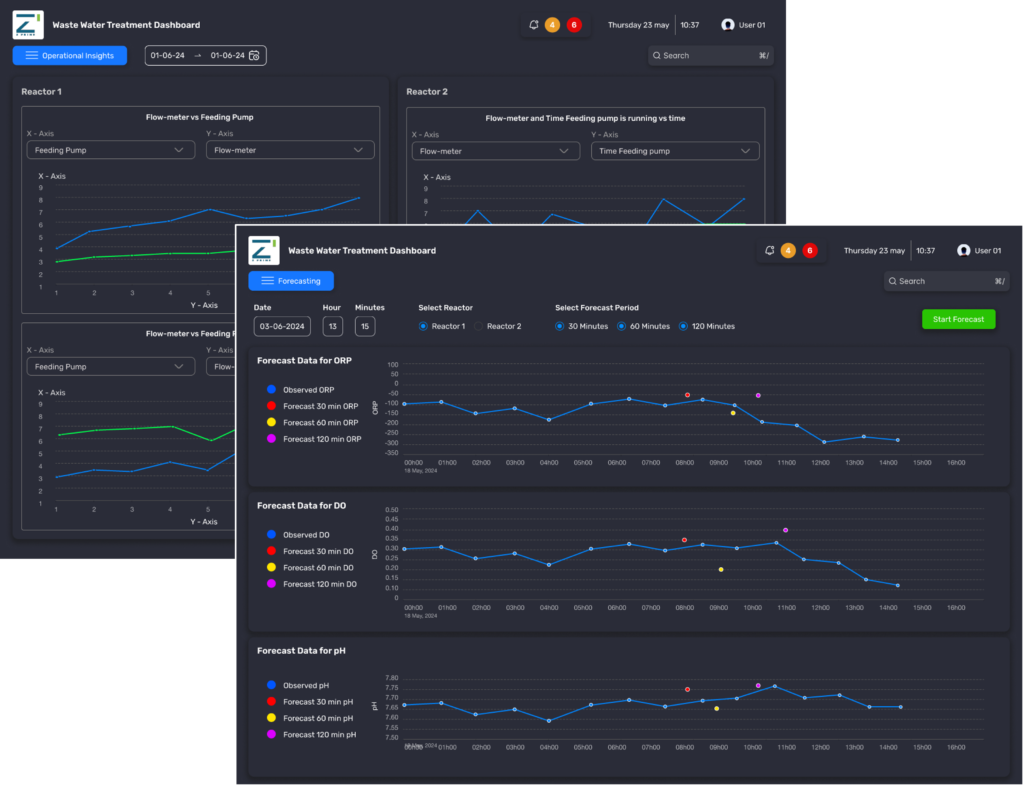

Z Prime Operational Efficiency solutions provide customisable dashboards and analytics tools to monitor and analyse data integrated from multiple sources. By providing a holistic view of plant-wide operations, Z Prime dashboards provide organisations with operational insights spanning manufacturing and water and wastewater plant productivity, equipment maintenance and the performance of industrial IoT sensors to help organisations enhance asset reliability, mitigate performance deterioration, and reduce operational costs.

For manufacturers, Powered by Z Prime’s advanced AI platform, the Operational Efficiency dashboards use predictive models capable of analysing historical and real-time data to identify trends and enable plant managers to proactively take preventive actions, minimise downtime, and maintain continuous production flow. This proactive Z Prime approach enhances Overall Equipment Effectiveness (OEE) by up to 70% and supports dynamic, performance-oriented maintenance strategies. Z Prime’s solutions enable organisations to minimise downtime and maximise operational efficiency.

In the water and wastewater industries, Z Prime’s solutions enable both conventional monitoring of water quality and plant performance, and high-level strategic decision-making with sustainability and circularity dimensions. Leveraging Z Prime’s advanced AI solutions, plant managers can customise tailored dashboards for tasks such as effluent quality compliance based on multiple key performance indicators.

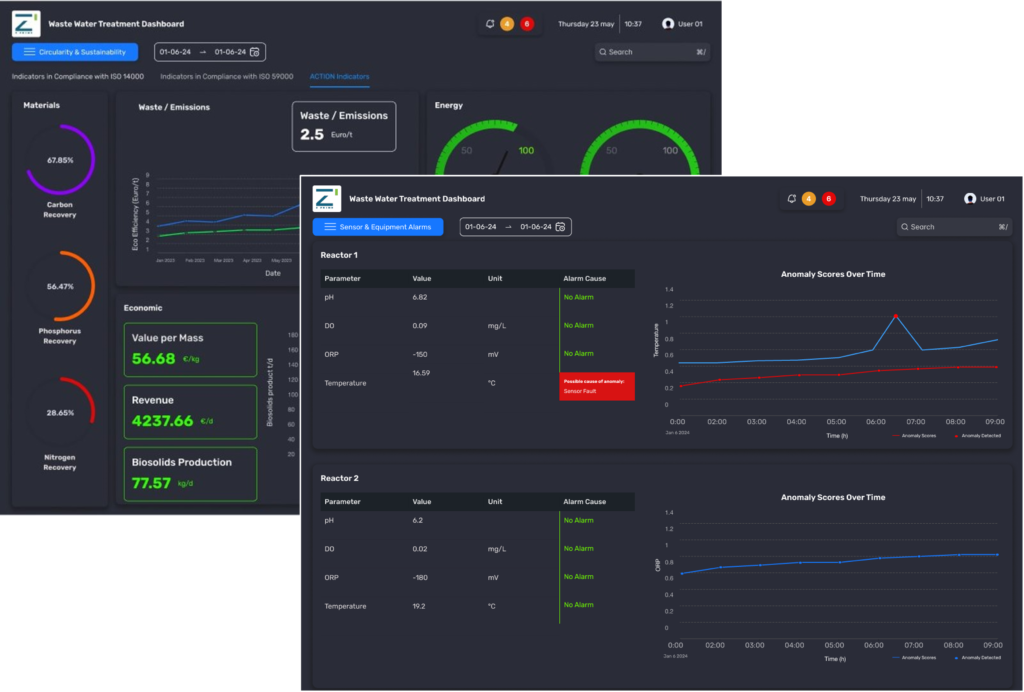

Z Prime Sustainability solutions enable organisations to enhance environmental reporting and set long-term sustainability goals to ensure adherence to industry regulations and standards, supported by advanced data analytics. Z Prime’s unique and comprehensive environmental and circularity assessment functions foster transparency and accountability while promoting sustainable and efficient resource use across sectors.

Z Prime innovative control solutions incorporate sustainability and circularity parameters into traditional industrial performance (e.g. Utilisation, Quality, Energy Efficiency and Inventory Control) optimisation strategies.

Aligned with ISO 14000 and ISO 59000 standard series, the Z Prime Sustainability solutions provide real-time insights into environmental impacts to support decision-making for rapid corrective actions. The solutions support a proactive approach to managing regulatory requirements and enhancing operational integrity.

The solutions use Z Prime Genomic AI-powered What-If Scenarios based on data monitored across operational and sustainability domains to support decision-making, enhance corporate resilience, and promote sustainable growth.

Z Prime’s Predictive Maintenance solutions for Cost and Risk-based maintenance planning provide optimal strategies for accurately predicting Remaining Useful Life of components and systems. The solutions leverage advanced AI algorithms and machine learning to estimate equipment lifespan, enabling manufacturers to transition from routine to predictive maintenance.

Through its digital twin solutions, Z Prime’s solutions are able to monitor and predict the remaining useful life of components, network of components (machine), and network of machines (process), employing a systems approach to achieve maximum resilience.

The Z Prime Predictive Maintenance solutions enhance Overall Equipment Effectiveness (OEE) by providing real-time monitoring and analysis of equipment performance. The solutions identify inefficiencies and predict maintenance needs, helping manufacturers maximise productivity, reduce downtime, and extend equipment lifespan.

The real-time data and insights support continuous improvement and operational excellence linked to the best strategy (Pre-empt, Wait, Appease) for maintenance planning. This enables organisations to reduce risk to operations and maintenance costs, minimise downtime and extend asset lifespan using preventive and pre-emptive wait strategies.

Z Prime Quality Monitoring solutions combine real-time data analytics with predictive modelling to enhance quality control, asset management, and cost efficiency. Powered by the Z Prime Genomic AI Platform, the solutions enhance accuracy by eliminating human error, detecting imperceptible defects and improving production quality, further cutting defect rates by 25-30% in systems with existing quality control solutions

For Structure and Surface Livening, the Z Prime Quality Monitoring solutions enable the integration of advanced materials and structural health monitoring to achieve net-zero carbon emissions in manufacturing sections such as aerospace. Using nanomaterials like carbon nanotubes and graphene, the solution creates intelligent, conductive surfaces that provide real-time data on structural conditions, improving the quality of design and manufacturing processes for sustainable, reliable aviation.

For Inline Quality Monitoring, the solutions use advanced sensors and machine learning algorithms to detect defects during the manufacturing process. Providing real-time feedback, it enables operators to make immediate adjustments and prevent defective products from reaching the market. Enhancing quality control, Z Prime Quality Monitoring solutions help manufacturers reduce waste, improve product quality, and increase customer satisfaction.

Z Prime Quality Improvement solutions enhance the accuracy and consistency of dispensing operations in manufacturing. Achieving a 95% reduction in defects, the Z Prime solutions minimise dependency on skilled labour, boost productivity, and empower proactive decision-making through real-time defect insights, preventing costly production delays.

In Laser-Based Additive Manufacturing (LBAM), the Z Prime Quality Improvement solutions achieve first-time perfect assemblies and reduce scrap by 80%. Integrating Digital Twin technology, multi-scale models, and enhanced AI/ML algorithms, Z Prime Quality Improvement for Additive Manufacturing Surface Treatment boosts the energy efficiency and sustainability of LBAM processes, addressing industry challenges and setting new standards for quality and environmental responsibility.

The Z Prime Quality Improvement solution for Optical Wafer Inspection uses high-resolution imaging and machine learning to detect defects in semiconductor wafers. Providing detailed analysis and classification of defects, the solution enables manufacturers to take prompt corrective actions and increase yield rates, reduce waste, and ensure high-quality semiconductor components.

For continuous quality improvement in Optoelectronic Assembly, Z Prime solutions ensure the reliability and performance of optoelectronic components using advanced AI and ML techniques. This advanced inspection system helps manufacturers enhance product quality, reduce rework, increase component recyclability and improve the overall reliability of optoelectronic devices.

The Z Prime Quality Improvement for the Food Industry enhances food safety and quality using advanced monitoring and inspection technologies. Monitoring critical parameters like temperature, humidity, and contamination levels in real-time ensures compliance with food safety standards. Powered by the Z Prime Genomic AI platform, the solutions help food manufacturers improve product quality, reduce waste, and ensure consumer safety.

Z Prime’s AI-powered Supply Chain solutions for Tracking and Traceability enable full reporting of product, material, energy and resource usage of the complete life cycle for end products. The solutions produce ISO and EU Directive-compliant Digital Passports including full Sustainability and Compliance Reports.

Implementing Z Prime’s Track & Trace monitoring throughout the internal and external company supply chain helps manufacturers achieve zero defects, minimise downtime, and enhance product quality. It also promotes sustainability through the integration of data on carbon neutrality and green manufacturing practices.

Z Prime solutions ensure product authenticity and quality by providing detailed Provenance information about the product’s origin, production process, and supply chain journey. The solutions leverage blockchain technology to offer an immutable record of product data, enhancing traceability and transparency.

Using the Z Prime Supply Chain Track and Trace solutions, companies can build consumer trust, meet regulatory requirements, and improve overall supply chain management.

Z Prime’s Genomic AI platform powers Cost and Risk Management solutions to co-optimise operational efficiency and quality with sustainability and circularity. Self-service dashboards correlate data from multiple sources and domains and present it in a view optimised for the business use case to create decision-ready information that improves reliability and operational efficiency.

For example, the Z Prime Financial Impact dashboard is an Embedded Cost and Risk-Based Decision Support System (CRDSS) integrating production and maintenance KPIs into a unified cost metric. Integrating data from multiple domains, the Z Prime Cost and Data Management dashboards help manufacturers identify inefficiencies, optimise resource allocation, and reduce production costs.

Powered by Z Prime’s Genomic AI Digital Twin platform, the Z Prime Cost and Data Management solutions enable accurate modelling and interpretation of data. The solutions identify complex patterns in data generated by operational processes and sensors to create proactive alerts on required actions, improving reliability and efficiency.

Combining advanced AI with historical data from both within the organisation and across industries, the Z Prime solution interprets those patterns to prioritise insights and provide steps for the required remedial actions.

Z Prime’s Data Management solutions enable organisations to manage data from multiple indicators across operational and sustainability domains through industry-specific and custom dashboards optimised for the business use case.

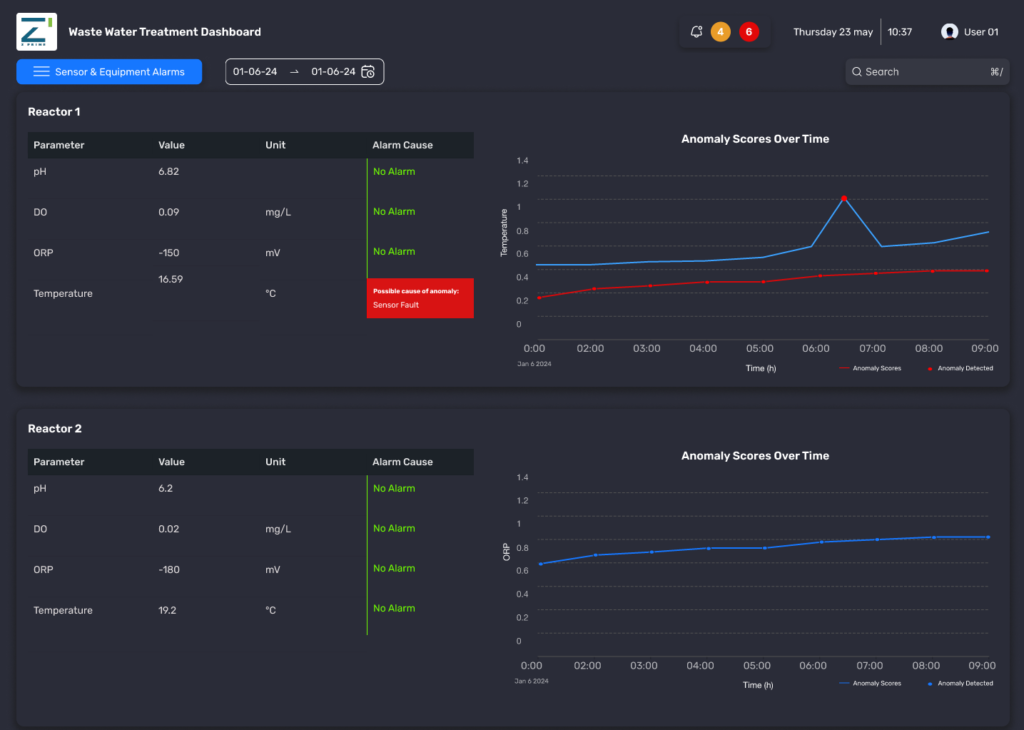

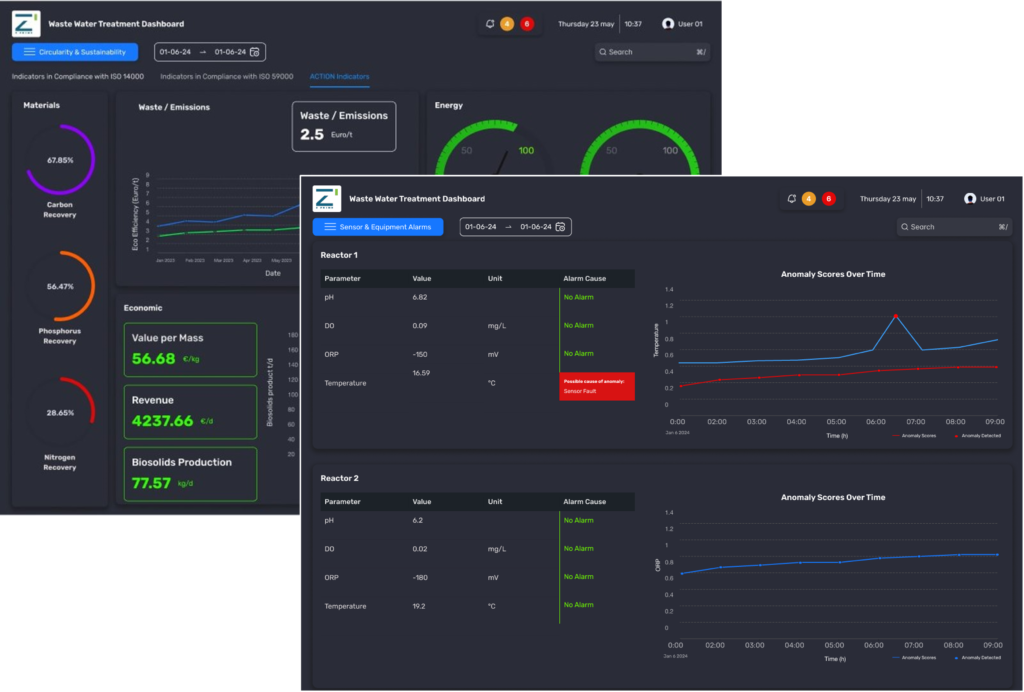

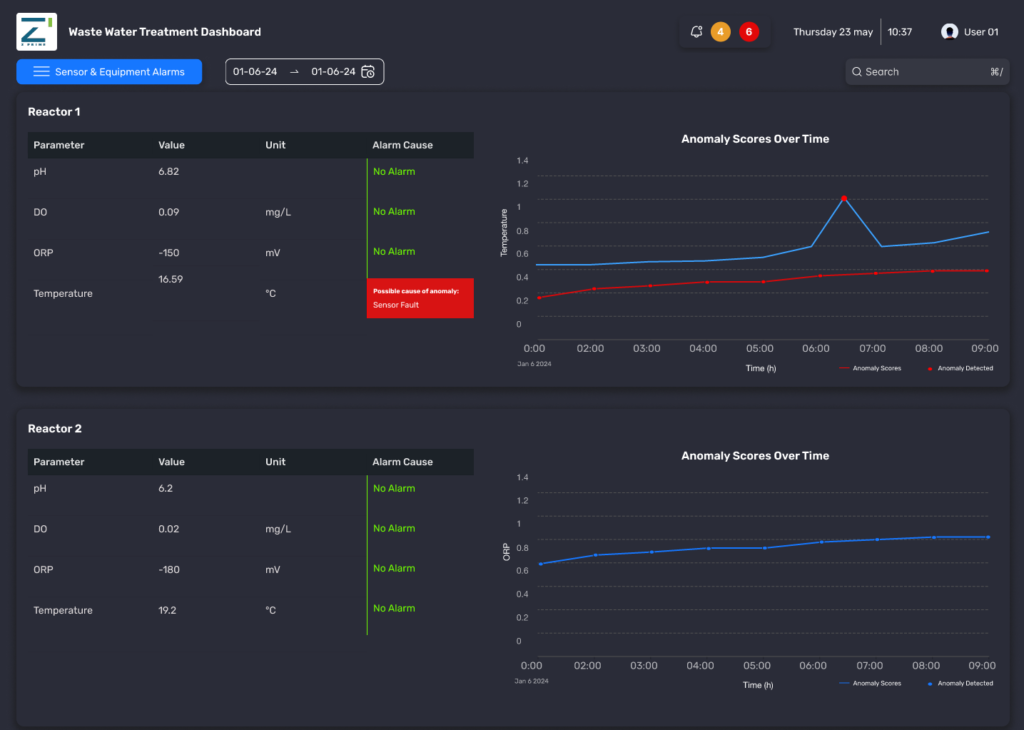

For water and wastewater plant operators, Z Prime’s Sensor Equipment Alarms & Interpretation Solutions identifies complex patterns in the data generated by operational processes and sensors to create proactive alerts on required actions, improving reliability and efficiency. Combining advanced AI with historical data from both within the organisation and across industries, the Z Prime solution interprets those patterns to prioritise insights and provide steps for the required remedial actions.

Leveraging the full power of AI-driven data management solutions, organisations can also use Z Prime’s self-service data analytics to create decision-ready information that improves reliability and operational efficiency. These self-service dashboards enable organisations to correlate data from multiple sources and present it in custom dashboards optimised for the business use case.

Z Prime’s Strategic Decision-Making Solutions empower organisations to set long-term sustainability goals and develop actionable evidence-based plans to achieve them. Integrating sustainability into strategic planning processes, Z Prime’s solutions help companies align operational performance with sustainability and circularity objectives.

Powered by Z Prime’s unique advanced AI system, the Z Prime Decision-Making Solutions analyse, interpret and transform data from multiple domains into a real-time knowledge management system that provides actionable insights and predictive simulations for balanced evidence-based decision-making.

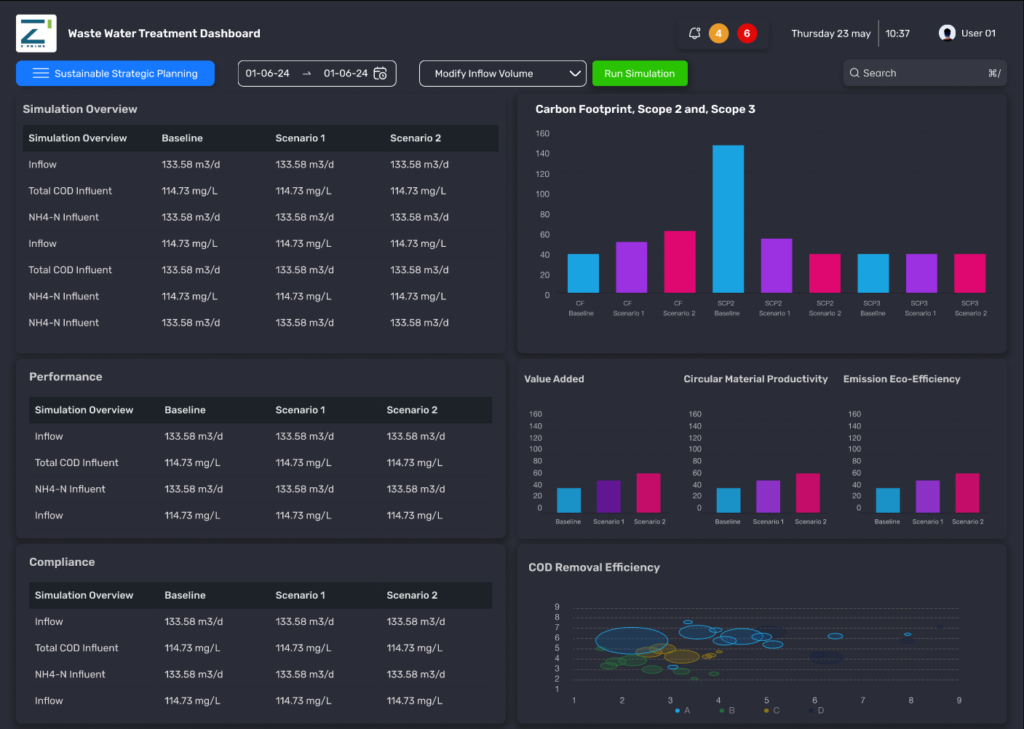

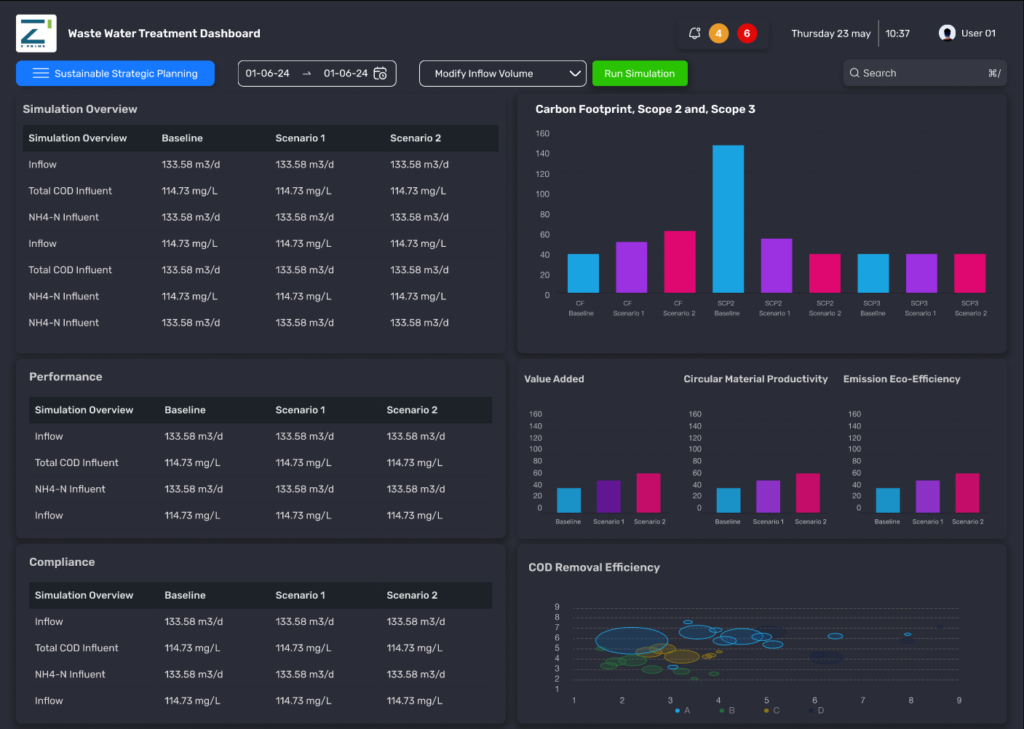

The Z Prime Sustainability Strategic Planning solution for water and wastewater organisations uses AI-powered What-If Scenarios based on data monitored across both operational and sustainability domains to support strategic decision-making, enhance corporate resilience, and promote sustainable growth.

Operational Efficiency Solutions

Z Prime Operational Efficiency solutions provide customisable dashboards and analytics tools to monitor and analyse data integrated from multiple sources. By providing a holistic view of plant-wide operations, Z Prime dashboards provide organisations with operational insights spanning manufacturing and water and wastewater plant productivity, equipment maintenance and the performance of industrial IoT sensors to help organisations enhance asset reliability, mitigate performance deterioration, and reduce operational costs.

For manufacturers, Powered by Z Prime’s advanced AI platform, the Operational Efficiency dashboards use predictive models capable of analysing historical and real-time data to identify trends and enable plant managers to proactively take preventive actions, minimise downtime, and maintain continuous production flow. This proactive Z Prime approach enhances Overall Equipment Effectiveness (OEE) by up to 70% and supports dynamic, performance-oriented maintenance strategies. Z Prime’s solutions enable organisations to minimise downtime and maximise operational efficiency.

In the water and wastewater industries, Z Prime’s solutions enable both conventional monitoring of water quality and plant performance, and high-level strategic decision-making with sustainability and circularity dimensions. Leveraging Z Prime’s advanced AI solutions, plant managers can customise tailored dashboards for tasks such as effluent quality compliance based on multiple key performance indicators.

Sustainability Solutions

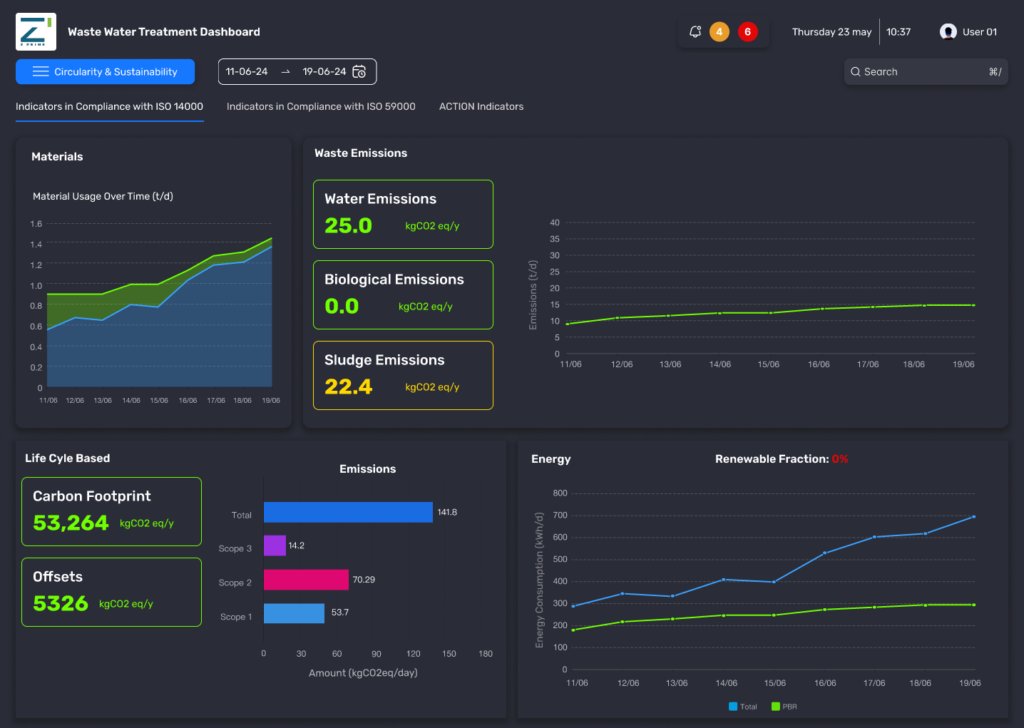

Z Prime Sustainability solutions enable organisations to enhance environmental reporting and set long-term sustainability goals to ensure adherence to industry regulations and standards, supported by advanced data analytics. Z Prime’s unique and comprehensive environmental and circularity assessment functions foster transparency and accountability while promoting sustainable and efficient resource use across sectors.

Z Prime innovative control solutions incorporate sustainability and circularity parameters into traditional industrial performance (e.g. Utilisation, Quality, Energy Efficiency and Inventory Control) optimisation strategies.

Aligned with ISO 14000 and ISO 59000 standard series, the Z Prime Sustainability solutions provide real-time insights into environmental impacts to support decision-making for rapid corrective actions. The solutions support a proactive approach to managing regulatory requirements and enhancing operational integrity.

The solutions use Z Prime Genomic AI-powered What-If Scenarios based on data monitored across operational and sustainability domains to support decision-making, enhance corporate resilience, and promote sustainable growth.

Predictive Maintenance Solutions

Z Prime’s Predictive Maintenance solutions for Cost and Risk-based maintenance planning provide optimal strategies for accurately predicting Remaining Useful Life of components and systems. The solutions leverage advanced AI algorithms and machine learning to estimate equipment lifespan, enabling manufacturers to transition from routine to predictive maintenance.

Through its digital twin solutions, Z Prime’s solutions are able to monitor and predict the remaining useful life of components, network of components (machine), and network of machines (process), employing a systems approach to achieve maximum resilience.

The Z Prime Predictive Maintenance solutions enhance Overall Equipment Effectiveness (OEE) by providing real-time monitoring and analysis of equipment performance. The solutions identify inefficiencies and predict maintenance needs, helping manufacturers maximise productivity, reduce downtime, and extend equipment lifespan.

The real-time data and insights support continuous improvement and operational excellence linked to the best strategy (Pre-empt, Wait, Appease) for maintenance planning. This enables organisations to reduce risk to operations and maintenance costs, minimise downtime and extend asset lifespan using preventive and pre-emptive wait strategies.

Quality Monitoring Solutions for systems with existing quality management tools

Z Prime Quality Monitoring solutions combine real-time data analytics with predictive modelling to enhance quality control, asset management, and cost efficiency. Powered by the Z Prime Genomic AI Platform, the solutions enhance accuracy by eliminating human error, detecting imperceptible defects and improving production quality, further cutting defect rates by 25-30% in systems with existing quality control solutions

For Structure and Surface Livening, the Z Prime Quality Monitoring solutions enable the integration of advanced materials and structural health monitoring to achieve net-zero carbon emissions in manufacturing sections such as aerospace. Using nanomaterials like carbon nanotubes and graphene, the solution creates intelligent, conductive surfaces that provide real-time data on structural conditions, improving the quality of design and manufacturing processes for sustainable, reliable aviation.

For Inline Quality Monitoring, the solutions use advanced sensors and machine learning algorithms to detect defects during the manufacturing process. Providing real-time feedback, it enables operators to make immediate adjustments and prevent defective products from reaching the market. Enhancing quality control, Z Prime Quality Monitoring solutions help manufacturers reduce waste, improve product quality, and increase customer satisfaction.

Advanced Defect Detection and Quality Improvement Solutions

Z Prime Quality Improvement solutions enhance the accuracy and consistency of dispensing operations in manufacturing. Achieving a 95% reduction in defects, the Z Prime solutions minimise dependency on skilled labour, boost productivity, and empower proactive decision-making through real-time defect insights, preventing costly production delays.

In Laser-Based Additive Manufacturing (LBAM), the Z Prime Quality Improvement solutions achieve first-time perfect assemblies and reduce scrap by 80%. Integrating Digital Twin technology, multi-scale models, and enhanced AI/ML algorithms, Z Prime Quality Improvement for Additive Manufacturing Surface Treatment boosts the energy efficiency and sustainability of LBAM processes, addressing industry challenges and setting new standards for quality and environmental responsibility.

The Z Prime Quality Improvement solution for Optical Wafer Inspection uses high-resolution imaging and machine learning to detect defects in semiconductor wafers. Providing detailed analysis and classification of defects, the solution enables manufacturers to take prompt corrective actions and increase yield rates, reduce waste, and ensure high-quality semiconductor components.

For continuous quality improvement in Optoelectronic Assembly, Z Prime solutions ensure the reliability and performance of optoelectronic components using advanced AI and ML techniques. This advanced inspection system helps manufacturers enhance product quality, reduce rework, increase component recyclability and improve the overall reliability of optoelectronic devices.

The Z Prime Quality Improvement for the Food Industry enhances food safety and quality using advanced monitoring and inspection technologies. Monitoring critical parameters like temperature, humidity, and contamination levels in real-time ensures compliance with food safety standards. Powered by the Z Prime Genomic AI platform, the solutions help food manufacturers improve product quality, reduce waste, and ensure consumer safety.

Supply Chain Track and Trace Solutions

Z Prime’s AI-powered Supply Chain solutions for Tracking and Traceability enable full reporting of product, material, energy and resource usage of the complete life cycle for end products. The solutions produce ISO and EU Directive-compliant Digital Passports including full Sustainability and Compliance Reports.

Implementing Z Prime’s Track & Trace monitoring throughout the internal and external company supply chain helps manufacturers achieve zero defects, minimise downtime, and enhance product quality. It also promotes sustainability through the integration of data on carbon neutrality and green manufacturing practices.

Z Prime solutions ensure product authenticity and quality by providing detailed Provenance information about the product’s origin, production process, and supply chain journey. The solutions leverage blockchain technology to offer an immutable record of product data, enhancing traceability and transparency.

Using the Z Prime Supply Chain Track and Trace solutions, companies can build consumer trust, meet regulatory requirements, and improve overall supply chain management.

Cost & Risk Management Solutions

Z Prime’s Genomic AI platform powers Cost and Risk Management solutions to co-optimise operational efficiency and quality with sustainability and circularity. Self-service dashboards correlate data from multiple sources and domains and present it in a view optimised for the business use case to create decision-ready information that improves reliability and operational efficiency.

For example, the Z Prime Financial Impact dashboard is an Embedded Cost and Risk-Based Decision Support System (CRDSS) integrating production and maintenance KPIs into a unified cost metric. Integrating data from multiple domains, the Z Prime Cost and Data Management dashboards help manufacturers identify inefficiencies, optimise resource allocation, and reduce production costs.

Powered by Z Prime’s Genomic AI Digital Twin platform, the Z Prime Cost and Data Management solutions enable accurate modelling and interpretation of data. The solutions identify complex patterns in data generated by operational processes and sensors to create proactive alerts on required actions, improving reliability and efficiency.

Combining advanced AI with historical data from both within the organisation and across industries, the Z Prime solution interprets those patterns to prioritise insights and provide steps for the required remedial actions.

Data Analytics, Knowledge Discovery and and Management Solutions

Z Prime’s Data Management solutions enable organisations to manage data from multiple indicators across operational and sustainability domains through industry-specific and custom dashboards optimised for the business use case.

For water and wastewater plant operators, Z Prime’s Sensor Equipment Alarms & Interpretation Solutions identifies complex patterns in the data generated by operational processes and sensors to create proactive alerts on required actions, improving reliability and efficiency. Combining advanced AI with historical data from both within the organisation and across industries, the Z Prime solution interprets those patterns to prioritise insights and provide steps for the required remedial actions.

Leveraging the full power of AI-driven data management solutions, organisations can also use Z Prime’s self-service data analytics to create decision-ready information that improves reliability and operational efficiency. These self-service dashboards enable organisations to correlate data from multiple sources and present it in custom dashboards optimised for the business use case.

Strategic Decision-Making Solutions

Z Prime’s Strategic Decision-Making Solutions empower organisations to set long-term sustainability goals and develop actionable evidence-based plans to achieve them. Integrating sustainability into strategic planning processes, Z Prime’s solutions help companies align operational performance with sustainability and circularity objectives.

Powered by Z Prime’s unique advanced AI system, the Z Prime Decision-Making Solutions analyse, interpret and transform data from multiple domains into a real-time knowledge management system that provides actionable insights and predictive simulations for balanced evidence-based decision-making.

The Z Prime Sustainability Strategic Planning solution for water and wastewater organisations uses AI-powered What-If Scenarios based on data monitored across both operational and sustainability domains to support strategic decision-making, enhance corporate resilience, and promote sustainable growth.

United Kingdom

Germany

United Arab Emirates

United Kingdom

Germany

United Arab Emirates