Sustainable and Compliant Industrial Operations for the Digital Era

Co-optimising Efficiency, Quality and Sustainability, Circularity

Co-optimising Efficiency, Quality and Sustainability, Circularity

The Z Prime platform is an industry-agnostic solution that collects multiple sources of data, models reality in a Genomic AI Platform, which wraps itself around the physical system using sophisticated analytics, provides deep insights and predictive simulations across multiple concurrent areas of an Enterprise: productivity, efficiency, quality, inventory and environmental impact.

The Z Prime Genomic AI Platform is a cloud-based service that is available in private/public/hybrid clouds or on-premise deployment options.

The Z Prime Insights software product leverages the data provided by the Z Prime Genomic AI Platform to provide the following key features.

Calculates general manufacturing KPIs such as productivity, resource utilisation, inventory, quality, and environmental impact, providing a holistic view of manufacturing performance. It enables a data driven and smart KPI visualisation platform with the ability to customise KPIs. It is the core product for a Self-Service Analytics solution.

Calculates general manufacturing KPIs such as productivity, resource utilisation, inventory, quality, and environmental impact, providing a holistic view of manufacturing performance. It enables a data driven and smart KPI visualisation platform with the ability to customise KPIs. It is the core product for a Self-Service Analytics solution.

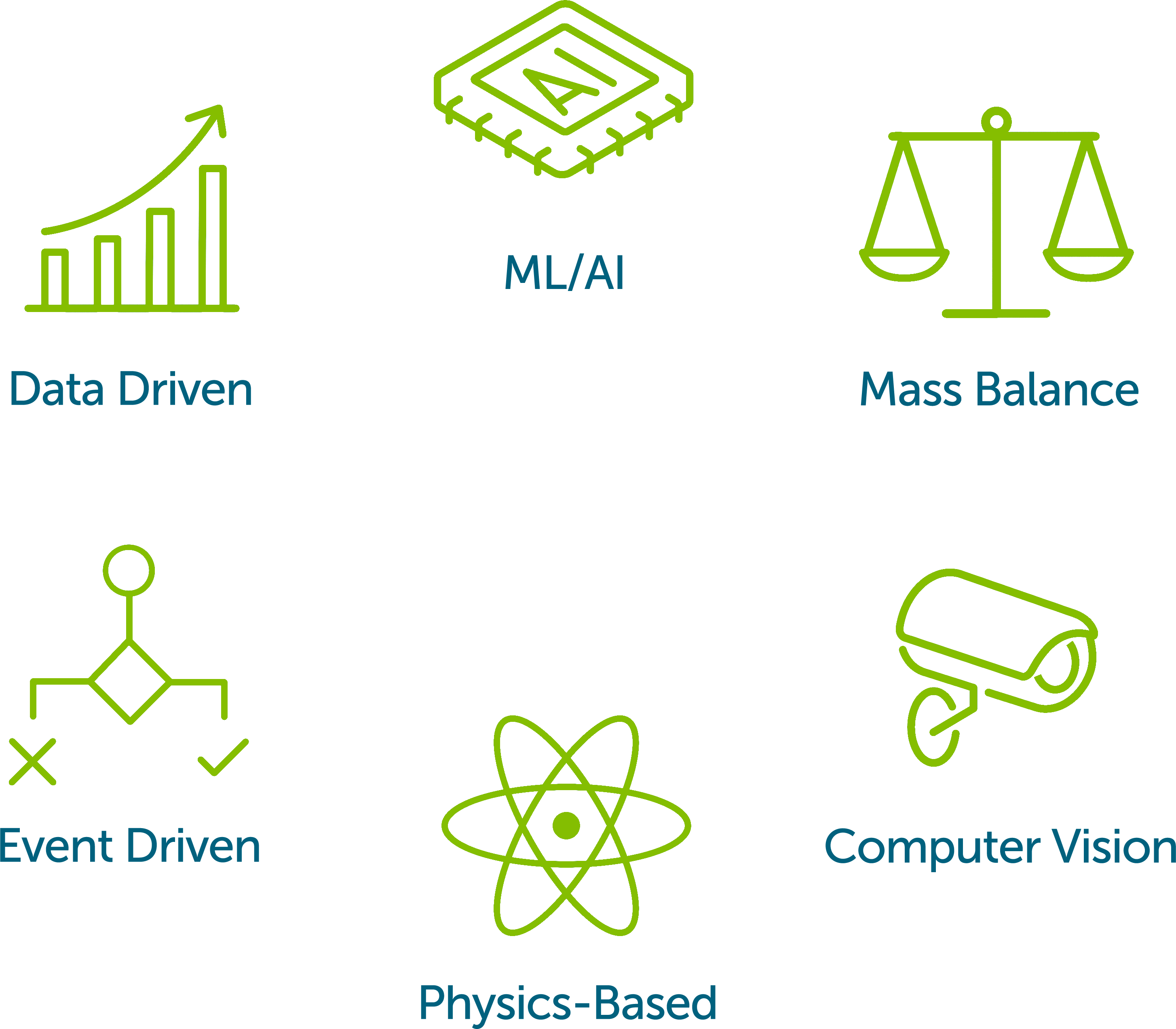

Uniquely translates production scenarios into cost and risk-based knowledge, linking the shop floor and the plant (engineering) to senior management. It creates a common language between all departments for improved tactical and strategic decision-making.

Uniquely translates production scenarios into cost and risk-based knowledge, linking the shop floor and the plant (engineering) to senior management. It creates a common language between all departments for improved tactical and strategic decision-making.

Enables sophisticated scenario planning, predictive simulation and decision-making that uniquely incorporates all KPIs consolidated in to a unified cost metric so that trade-off decisions can be made across different management domains using common criteria. Key components are Cost & Risk function, Optimisation and Insight, Simulation and Forecasting.

Enables sophisticated scenario planning, predictive simulation and decision-making that uniquely incorporates all KPIs consolidated in to a unified cost metric so that trade-off decisions can be made across different management domains using common criteria. Key components are Cost & Risk function, Optimisation and Insight, Simulation and Forecasting.

The Embedded Cost and Risk-Based Decision Support System (CRDSS) merges production and maintenance metrics into a single cost metric, offering decision-makers a comprehensive real-time and look ahead view of financial outcomes. It provides scenario-based decision support, precise cost estimation per product, and adheres to sustainability standards (ISO59020 compliant), enhancing financial planning and cost optimisation.

The Embedded Cost and Risk-Based Decision Support System (CRDSS) merges production and maintenance metrics into a single cost metric, offering decision-makers a comprehensive real-time and look ahead view of financial outcomes. It provides scenario-based decision support, precise cost estimation per product, and adheres to sustainability standards (ISO59020 compliant), enhancing financial planning and cost optimisation.

Fast-forwards the digital twin time clock to simulate future conditions and provide predictive analysis. All the Cost, Risk and Optimisation functions are available in the simulated-future environment

Fast-forwards the digital twin time clock to simulate future conditions and provide predictive analysis. All the Cost, Risk and Optimisation functions are available in the simulated-future environment

Enables predictive scenario planning by optimising for certain objectives such as cost, quality, energy, operational performance, carbon footprint, green maintenance scheduling, circularity and economics of production. It provides actionable recommendations to address inefficiencies and enhance overall system performance.

Enables predictive scenario planning by optimising for certain objectives such as cost, quality, energy, operational performance, carbon footprint, green maintenance scheduling, circularity and economics of production. It provides actionable recommendations to address inefficiencies and enhance overall system performance.

Detects, predicts, and prevents defects and abnormalities in electronics, metals, food and water processes using a combination of sensors (including high-definition and hyper-spectral cameras and X-Ray cameras) and AI/ML algorithms resulting in, in some cases, a 99.3% improvement in inspection times. Accuracy resolution is enough to detect bacteria and contaminants on food, and indeed the freshness of food.

Detects, predicts, and prevents defects and abnormalities in electronics, metals, food and water processes using a combination of sensors (including high-definition and hyper-spectral cameras and X-Ray cameras) and AI/ML algorithms resulting in, in some cases, a 99.3% improvement in inspection times. Accuracy resolution is enough to detect bacteria and contaminants on food, and indeed the freshness of food.

Enhances routine maintenance planning to improve Overall Equipment Effectiveness (OEE) and minimise stoppages by calculating the optimal Routine Maintenance Frequency (RMF) based on Remaining Useful Life (RUL), targeting precise timings for maintenance to prevent unplanned downtime. The innovative Remaining Useful Life for Zero-Breakdown (RULZ) system predicts the exact timing for maintenance interventions, utilising a digital twin to mirror the operational environment and a unique cost and risk-based algorithm to optimise schedules and adapt to each operational context.

Enhances routine maintenance planning to improve Overall Equipment Effectiveness (OEE) and minimise stoppages by calculating the optimal Routine Maintenance Frequency (RMF) based on Remaining Useful Life (RUL), targeting precise timings for maintenance to prevent unplanned downtime. The innovative Remaining Useful Life for Zero-Breakdown (RULZ) system predicts the exact timing for maintenance interventions, utilising a digital twin to mirror the operational environment and a unique cost and risk-based algorithm to optimise schedules and adapt to each operational context.

Enhances device authentication and product integrity in electronics and general security, employing intrinsic variations in surface and internal features (using an optical camera and X-Ray imaging) to deter counterfeiting and ensure track & traceability, by comparing the digital fingerprint with a validated database record. It is also used in assessing items in security operations such as passenger luggage at airports, or integration with Supply Chain management systems.

Enhances device authentication and product integrity in electronics and general security, employing intrinsic variations in surface and internal features (using an optical camera and X-Ray imaging) to deter counterfeiting and ensure track & traceability, by comparing the digital fingerprint with a validated database record. It is also used in assessing items in security operations such as passenger luggage at airports, or integration with Supply Chain management systems.

Provenance enhances security by authenticating devices and products through intrinsic surface and internal feature variations, using optical camera and X-ray imaging. It can be used in security operations like airport luggage assessment and general product integrity assurance.

Provenance enhances security by authenticating devices and products through intrinsic surface and internal feature variations, using optical camera and X-ray imaging. It can be used in security operations like airport luggage assessment and general product integrity assurance.

Ensures track and traceability by comparing digital fingerprints of devices and products with validated database records, using optical camera and X-ray imaging to prevent counterfeiting and maintain product integrity in supply chain management.

Ensures track and traceability by comparing digital fingerprints of devices and products with validated database records, using optical camera and X-ray imaging to prevent counterfeiting and maintain product integrity in supply chain management.

Provides precise KPIs for compliance with environmental regulations transforming industry data into actionable circularity, carbon footprint, sustainability, and ESG KPIs, that ensures effective tracking, monitoring, and decision-making across the supply chain.

Provides precise KPIs for compliance with environmental regulations transforming industry data into actionable circularity, carbon footprint, sustainability, and ESG KPIs, that ensures effective tracking, monitoring, and decision-making across the supply chain.

Transforms industry data into circularity KPIs as per ISO 59020, guiding eco-friendly decisions. By filling data gaps, it ensures precise KPIs, offering tailored visualisations for clear monitoring and compliance checks, thereby reinforcing circularity tracking and claim validation. It also provides scores across the supply chain for carbon footprint and sustainability, enhancing trust and confidence.

Transforms industry data into circularity KPIs as per ISO 59020, guiding eco-friendly decisions. By filling data gaps, it ensures precise KPIs, offering tailored visualisations for clear monitoring and compliance checks, thereby reinforcing circularity tracking and claim validation. It also provides scores across the supply chain for carbon footprint and sustainability, enhancing trust and confidence.

Processes industry data into carbon footprint KPIs, following ISO 14067, to support reduction and offsetting efforts. The methodologies ensure accurate KPIs, aiding carbon management. The tool's visualisations help users monitor emissions, verify compliance, and track carbon, besides assisting in choosing carbon offset partners and planning future budgets.

Processes industry data into carbon footprint KPIs, following ISO 14067, to support reduction and offsetting efforts. The methodologies ensure accurate KPIs, aiding carbon management. The tool's visualisations help users monitor emissions, verify compliance, and track carbon, besides assisting in choosing carbon offset partners and planning future budgets.

Converts industry data into sustainability KPIs, in line with ISOs 140001 and 14040/44, facilitating environmental management. Its assessments fill data gaps, enabling precise KPIs and customised visualisations for tracking and compliance. It aids in validating environmental product declarations and enhancing sustainability performance, simplifying decision-making.

Converts industry data into sustainability KPIs, in line with ISOs 140001 and 14040/44, facilitating environmental management. Its assessments fill data gaps, enabling precise KPIs and customised visualisations for tracking and compliance. It aids in validating environmental product declarations and enhancing sustainability performance, simplifying decision-making.

Automates the translation of company reports and data into ESG compliance metrics, generating ESG reports and tracking goals. It acts as a central data management hub, eliminating silos for enhanced cross-departmental learning, resource optimisation, and compliance oversight across multiple sites or regions. This streamlines ESG reporting in alignment with the Corporate Sustainability Reporting Directive (CSRD). By integrating company-level data aggregation and processing, it simplifies the creation of Environmental, Social, and Governance reports, offering a significant tool for automating compliance and reporting processes.

Automates the translation of company reports and data into ESG compliance metrics, generating ESG reports and tracking goals. It acts as a central data management hub, eliminating silos for enhanced cross-departmental learning, resource optimisation, and compliance oversight across multiple sites or regions. This streamlines ESG reporting in alignment with the Corporate Sustainability Reporting Directive (CSRD). By integrating company-level data aggregation and processing, it simplifies the creation of Environmental, Social, and Governance reports, offering a significant tool for automating compliance and reporting processes.

At the heart of the Z Prime software platform is the Z Prime Genomic AI Platform that turns data into a real-time digital replica of an industrial organisation to enable insights and advanced decision support systems including predictive simulation and co-optimising of operational and environmental objectives.

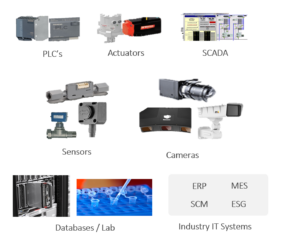

Z Prime’s iDAQ is an intelligent data acquisition system that collects, cleans, and pre-processes data from both Operational Technology (OT) and Information Technology (IT) sources within a manufacturing environment. The system integrates data from a variety of OT devices such as sensors, SCADA systems, PLCs, cameras, and actuators.

Co-optimising Efficiency, Quality and Sustainability, Circularity

The Z Prime platform is an industry-agnostic solution that collects multiple sources of data, models reality in a Genomic AI Platform, which wraps itself around the physical system using sophisticated analytics, provides deep insights and predictive simulations across multiple concurrent areas of an Enterprise: productivity, efficiency, quality, inventory and environmental impact.

The Z Prime Genomic AI Platform is a cloud-based service that is available in private/public/hybrid clouds or on-premise deployment options.

The Z Prime Insights software product leverages the data provided by the Z Prime Genomic AI Platform to provide the following key features.

Calculates general manufacturing KPIs such as productivity, resource utilisation, inventory, quality, and environmental impact, providing a holistic view of manufacturing performance. It enables a data driven and smart KPI visualisation platform with the ability to customise KPIs. It is the core product for a Self-Service Analytics solution.

Calculates general manufacturing KPIs such as productivity, resource utilisation, inventory, quality, and environmental impact, providing a holistic view of manufacturing performance. It enables a data driven and smart KPI visualisation platform with the ability to customise KPIs. It is the core product for a Self-Service Analytics solution.

Uniquely translates production scenarios into cost and risk-based knowledge, linking the shop floor and the plant (engineering) to senior management. It creates a common language between all departments for improved tactical and strategic decision-making.

Uniquely translates production scenarios into cost and risk-based knowledge, linking the shop floor and the plant (engineering) to senior management. It creates a common language between all departments for improved tactical and strategic decision-making.

Enables sophisticated scenario planning, predictive simulation and decision-making that uniquely incorporates all KPIs consolidated in to a unified cost metric so that trade-off decisions can be made across different management domains using common criteria. Key components are Cost & Risk function, Optimisation and Insight, Simulation and Forecasting.

Enables sophisticated scenario planning, predictive simulation and decision-making that uniquely incorporates all KPIs consolidated in to a unified cost metric so that trade-off decisions can be made across different management domains using common criteria. Key components are Cost & Risk function, Optimisation and Insight, Simulation and Forecasting.

The Embedded Cost and Risk-Based Decision Support System (CRDSS) merges production and maintenance metrics into a single cost metric, offering decision-makers a comprehensive real-time and look ahead view of financial outcomes. It provides scenario-based decision support, precise cost estimation per product, and adheres to sustainability standards (ISO59020 compliant), enhancing financial planning and cost optimisation.

The Embedded Cost and Risk-Based Decision Support System (CRDSS) merges production and maintenance metrics into a single cost metric, offering decision-makers a comprehensive real-time and look ahead view of financial outcomes. It provides scenario-based decision support, precise cost estimation per product, and adheres to sustainability standards (ISO59020 compliant), enhancing financial planning and cost optimisation.

Fast-forwards the digital twin time clock to simulate future conditions and provide predictive analysis. All the Cost, Risk and Optimisation functions are available in the simulated-future environment

Fast-forwards the digital twin time clock to simulate future conditions and provide predictive analysis. All the Cost, Risk and Optimisation functions are available in the simulated-future environment

Enables predictive scenario planning by optimising for certain objectives such as cost, quality, energy, operational performance, carbon footprint, green maintenance scheduling, circularity and economics of production. It provides actionable recommendations to address inefficiencies and enhance overall system performance.

Enables predictive scenario planning by optimising for certain objectives such as cost, quality, energy, operational performance, carbon footprint, green maintenance scheduling, circularity and economics of production. It provides actionable recommendations to address inefficiencies and enhance overall system performance.

Enhances routine maintenance planning to improve Overall Equipment Effectiveness (OEE) and minimise stoppages by calculating the optimal Routine Maintenance Frequency (RMF) based on Remaining Useful Life (RUL), targeting precise timings for maintenance to prevent unplanned downtime. The innovative Remaining Useful Life for Zero-Breakdown (RULZ) system predicts the exact timing for maintenance interventions, utilising a digital twin to mirror the operational environment and a unique cost and risk-based algorithm to optimise schedules and adapt to each operational context.

Enhances routine maintenance planning to improve Overall Equipment Effectiveness (OEE) and minimise stoppages by calculating the optimal Routine Maintenance Frequency (RMF) based on Remaining Useful Life (RUL), targeting precise timings for maintenance to prevent unplanned downtime. The innovative Remaining Useful Life for Zero-Breakdown (RULZ) system predicts the exact timing for maintenance interventions, utilising a digital twin to mirror the operational environment and a unique cost and risk-based algorithm to optimise schedules and adapt to each operational context.

Detects, predicts, and prevents defects and abnormalities in electronics, metals, food and water processes using a combination of sensors (including high-definition and hyper-spectral cameras and X-Ray cameras) and AI/ML algorithms resulting in, in some cases, a 99.3% improvement in inspection times. Accuracy resolution is enough to detect bacteria and contaminants on food, and indeed the freshness of food.

Detects, predicts, and prevents defects and abnormalities in electronics, metals, food and water processes using a combination of sensors (including high-definition and hyper-spectral cameras and X-Ray cameras) and AI/ML algorithms resulting in, in some cases, a 99.3% improvement in inspection times. Accuracy resolution is enough to detect bacteria and contaminants on food, and indeed the freshness of food.

Enhances device authentication and product integrity in electronics and general security, employing intrinsic variations in surface and internal features (using an optical camera and X-Ray imaging) to deter counterfeiting and ensure track & traceability, by comparing the digital fingerprint with a validated database record. It is also used in assessing items in security operations such as passenger luggage at airports, or integration with Supply Chain management systems.

Enhances device authentication and product integrity in electronics and general security, employing intrinsic variations in surface and internal features (using an optical camera and X-Ray imaging) to deter counterfeiting and ensure track & traceability, by comparing the digital fingerprint with a validated database record. It is also used in assessing items in security operations such as passenger luggage at airports, or integration with Supply Chain management systems.

Ensures track and traceability by comparing digital fingerprints of devices and products with validated database records, using optical camera and X-ray imaging to prevent counterfeiting and maintain product integrity in supply chain management.

Ensures track and traceability by comparing digital fingerprints of devices and products with validated database records, using optical camera and X-ray imaging to prevent counterfeiting and maintain product integrity in supply chain management.

Provenance enhances security by authenticating devices and products through intrinsic surface and internal feature variations, using optical camera and X-ray imaging. It can be used in security operations like airport luggage assessment and general product integrity assurance.

Provenance enhances security by authenticating devices and products through intrinsic surface and internal feature variations, using optical camera and X-ray imaging. It can be used in security operations like airport luggage assessment and general product integrity assurance.

Provides precise KPIs for compliance with environmental regulations transforming industry data into actionable circularity, carbon footprint, sustainability, and ESG KPIs, that ensures effective tracking, monitoring, and decision-making across the supply chain.

Provides precise KPIs for compliance with environmental regulations transforming industry data into actionable circularity, carbon footprint, sustainability, and ESG KPIs, that ensures effective tracking, monitoring, and decision-making across the supply chain.

Processes industry data into carbon footprint KPIs, following ISO 14067, to support reduction and offsetting efforts. The methodologies ensure accurate KPIs, aiding carbon management. The tool's visualisations help users monitor emissions, verify compliance, and track carbon, besides assisting in choosing carbon offset partners and planning future budgets.

Processes industry data into carbon footprint KPIs, following ISO 14067, to support reduction and offsetting efforts. The methodologies ensure accurate KPIs, aiding carbon management. The tool's visualisations help users monitor emissions, verify compliance, and track carbon, besides assisting in choosing carbon offset partners and planning future budgets.

Converts industry data into sustainability KPIs, in line with ISOs 140001 and 14040/44, facilitating environmental management. Its assessments fill data gaps, enabling precise KPIs and customised visualisations for tracking and compliance. It aids in validating environmental product declarations and enhancing sustainability performance, simplifying decision-making.

Converts industry data into sustainability KPIs, in line with ISOs 140001 and 14040/44, facilitating environmental management. Its assessments fill data gaps, enabling precise KPIs and customised visualisations for tracking and compliance. It aids in validating environmental product declarations and enhancing sustainability performance, simplifying decision-making.

Transforms industry data into circularity KPIs as per ISO 59020, guiding eco-friendly decisions. By filling data gaps, it ensures precise KPIs, offering tailored visualisations for clear monitoring and compliance checks, thereby reinforcing circularity tracking and claim validation. It also provides scores across the supply chain for carbon footprint and sustainability, enhancing trust and confidence.

Transforms industry data into circularity KPIs as per ISO 59020, guiding eco-friendly decisions. By filling data gaps, it ensures precise KPIs, offering tailored visualisations for clear monitoring and compliance checks, thereby reinforcing circularity tracking and claim validation. It also provides scores across the supply chain for carbon footprint and sustainability, enhancing trust and confidence.

Automates the translation of company reports and data into ESG compliance metrics, generating ESG reports and tracking goals. It acts as a central data management hub, eliminating silos for enhanced cross-departmental learning, resource optimisation, and compliance oversight across multiple sites or regions. This streamlines ESG reporting in alignment with the Corporate Sustainability Reporting Directive (CSRD). By integrating company-level data aggregation and processing, it simplifies the creation of Environmental, Social, and Governance reports, offering a significant tool for automating compliance and reporting processes.

Automates the translation of company reports and data into ESG compliance metrics, generating ESG reports and tracking goals. It acts as a central data management hub, eliminating silos for enhanced cross-departmental learning, resource optimisation, and compliance oversight across multiple sites or regions. This streamlines ESG reporting in alignment with the Corporate Sustainability Reporting Directive (CSRD). By integrating company-level data aggregation and processing, it simplifies the creation of Environmental, Social, and Governance reports, offering a significant tool for automating compliance and reporting processes.

At the heart of the Z Prime software platform is the Z Prime Genomic AI Platform that turns data into a real-time digital replica of an industrial organisation to enable insights and advanced decision support systems including predictive simulation and co-optimising of operational and environmental objectives.

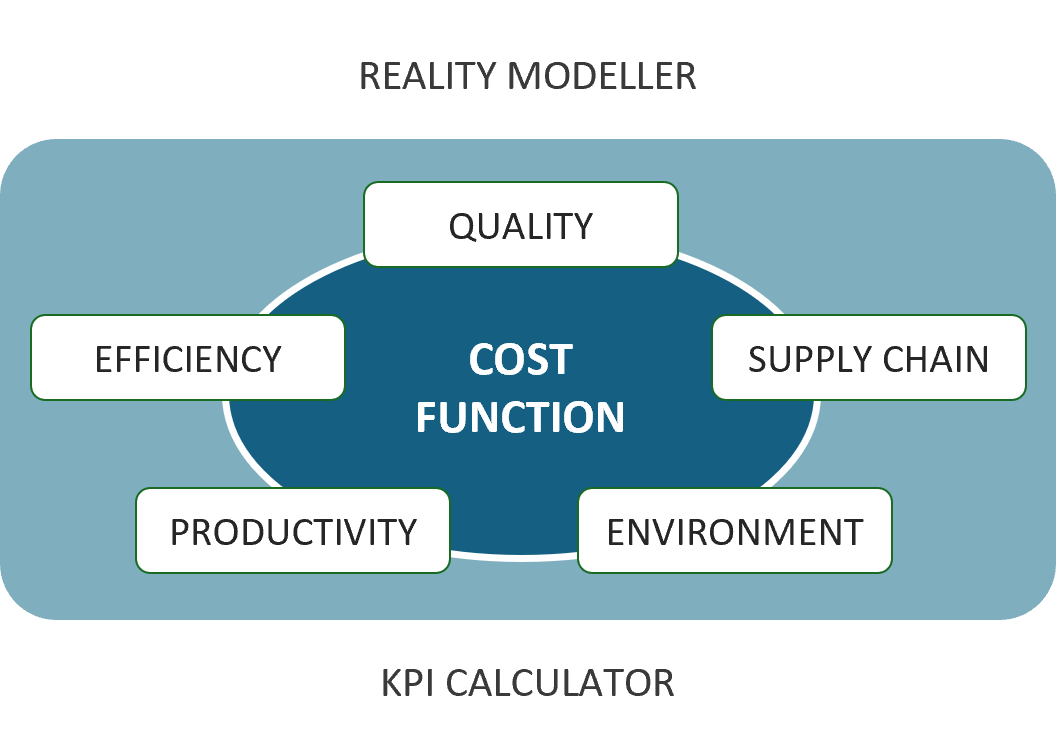

Taking pre-processed data from the iDaQ, the Big Data Collider analyses it, understands its context and relationships with other data and manipulates and fuses it in ways that enable it to be used by relevant models in the Reality Modeller.

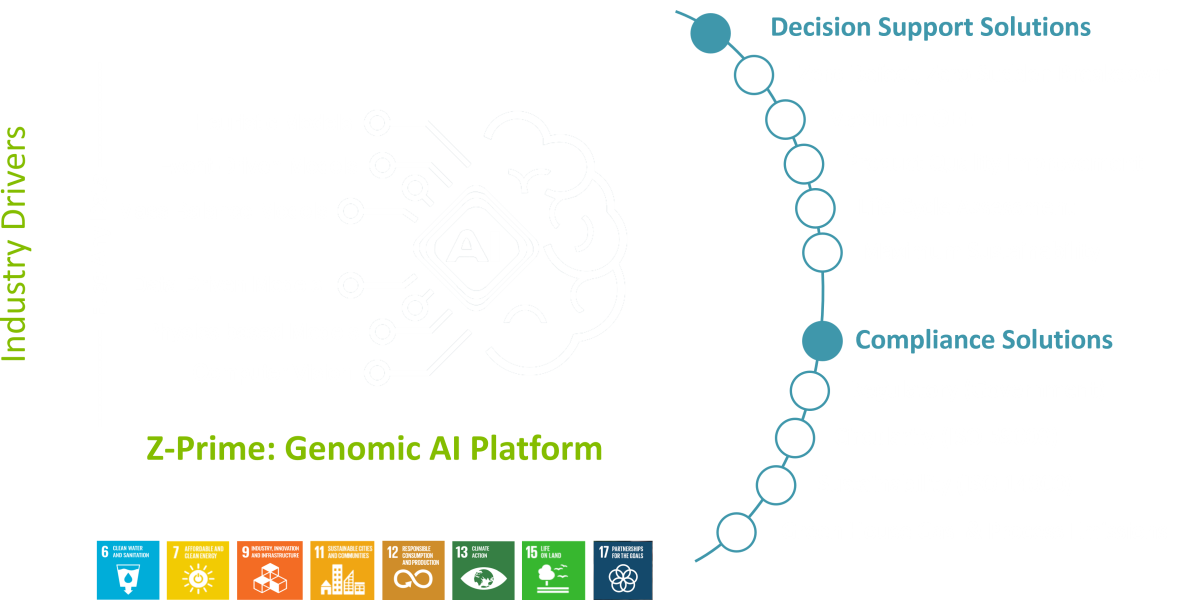

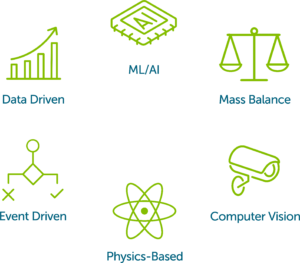

Z Prime leverages several different models to create a digital twin including ML/AI, data-driven, mass balance, event-driven, physics-based and computer vision models. It also includes the unique Genomic of Industrial Process™ that models causal relationships against desired and undesired outcomes, and identifies the underlying drivers (the ‘genes’) enabling complex diagnosis and rectification of manufacturing process defects beyond the scope of standard Deep Neural Network algorithms.

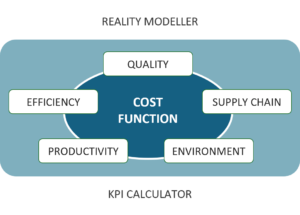

Data is used by the models to present real-time data that comprehensively models reality through complex calculations integrated across the key areas of: productivity (availability, OEE), efficiency (energy, discrete energy profiling), quality (defects, reliability), inventory (track & traceability, production scheduling) and environmental impacts (carbon footprint, circularity, sustainability).

Z Prime’s iDAQ is an intelligent data acquisition system that collects, cleans, and pre-processes data from both Operational Technology (OT) and Information Technology (IT) sources within a manufacturing environment. The system integrates data from a variety of OT devices such as sensors, SCADA systems, PLCs, cameras, and actuators.

iDAQ efficiently handles data from IT systems including ERP (Enterprise Resource Planning), MES (Manufacturing Execution Systems), SCM (Supply Chain Management), and ESG (Environmental, Social, and Governance) databases.

More than simple data collection and formatting, it utilises five critical checks on the raw data, conducting preliminary data preparation and analytics to package it for processing by the Big Data Collider.

United Kingdom

Germany

United Arab Emirates

United Kingdom

Germany

United Arab Emirates