Productivity. Efficiency. Quality. If these are to be anything more than just admirable buzzwords in modern, complex manufacturing, the complex processes behind them need to modernised too. Enter Genomics of Industrial Processes.

Genomics of Industrial Processes is an advanced AI methodology that transforms how manufacturers predict, prevent and manage defects in real-time. Inspired by the principles of genetic analysis, it uses Genomics of Industrial Processes to treat each event within a complex industrial process as a “process gene.” This allows for a proactive approach, where sequences of events are tracked, analysed, and managed to maintain product quality and optimise efficiency.

What is Genomics of Industrial Processes?

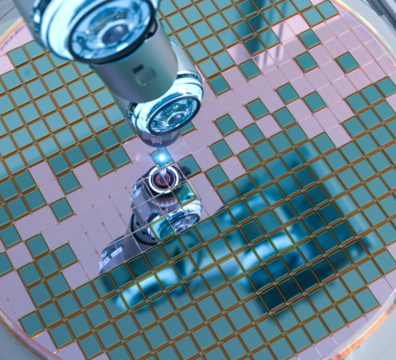

Genomics of Industrial Processes identifies and tracks individual events during complex processes, treating them as discrete changes in the system’s state. These events are strung together like a genetic sequence, where each “gene” represents critical input and output parameters at specific times. Just as biological genes can predict traits or diseases, these “process genes” can forecast and prevent defects in complex processes, such as those typical of semiconductor manufacturing or water and wastewater treatment plants.

By understanding and mapping these sequences of events, manufacturers can intervene early, adjusting parameters to avoid potential defects. This proactive approach marks a significant departure from traditional quality control, which often detects defects only after they have already occurred.

How Genomics of Industrial Processes Works

Genomics of Industrial Processes is based on key principles that enable real-time monitoring and proactive quality control:

- Event Tracking and Clustering: Events within a process are continuously tracked and grouped into sequences called process genes. Each sequence provides detailed information on the system’s inputs and outputs, similar to how a DNA sequence holds genetic information.

- Causal Links and Pathways: The sequences of events reveal causal links between changes in the system’s state and the quality of the final product. Identifying these links allows manufacturers to detect patterns that may lead to defects and make real-time adjustments.

- Predictive Defect Identification: Process genes can be aligned to predict potential defects. If a series of events indicates a risk of defect, manufacturers can proactively disrupt the sequence and make necessary adjustments to maintain quality.

- Markovian Process Chains: The state of the system at any moment depends solely on its previous state, creating a predictable and manageable process flow.

Download our latest whitepaper, “Unlocking Zero-Defect Manufacturing with Genomics of Industrial Processes”, to find out more.

The Role of AI and ML in Genomics of Industrial Processes

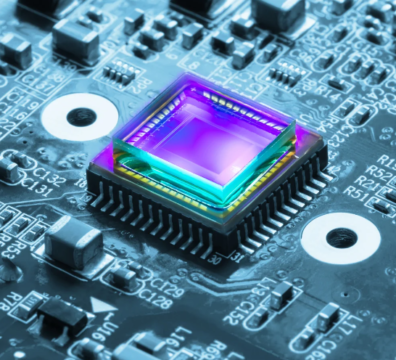

CRDSS A vital component of Genomics of Industrial Processes is the use of artificial intelligence (AI) and machine learning (ML). By training AI models on historical process data, these systems learn to identify sequences that may lead to defects. AI models analyse key factors such as temperature, pressure, and humidity to predict and prevent defects.

Unlike traditional ML methods, Genomics of Industrial Processes techniques are designed for real-time decision-making, data-efficient learning and understanding causality. This approach enables manufacturers to take corrective action immediately, preventing defects rather than reacting to them.

Genomics of Industrial Processes vs. Classical Machine Learning Techniques

Genomics of Industrial Processes offers several advantages over traditional ML approaches like random forest regression and k-nearest neighbours (KNN). Key advantages that differentiate Genomics of Industrial Processes from classical AI/ML include:

- Data-Efficient Learning: It focuses on event sequences, allowing for faster learning with smaller datasets.

- Real-Time Decision Making: Genomics of Industrial Processes continuously updates its models, making instant adjustments based on new data.

- Dimensionality Reduction: It simplifies data to focus on the most relevant factors, reducing computational complexity.

- Causal Understanding: Unlike traditional ML, Genomics of Industrial Processes identifies the root causes of defects, enabling targeted actions.

Expanding the Impact of Genomics of Industrial Processes

We look at the application of Genomics of Industrial Processes in industry in more detail in this accompanying blog but suffice it to say the applications of Genomics of Industrial Processes extend beyond quality control. Use cases for Genomics of Industrial Processes extend across complex processes where multiple – sometimes competing – data domains have to be co-optimised. These can include, but are not limited to:

- Predictive Maintenance: Monitoring event sequences helps predict equipment failures, reducing downtime and extending machinery life.

- Supply Chain Optimisation: Analysing event sequences can identify bottlenecks, improving material flow and delivery timelines.

- Sustainability: By identifying inefficiencies in production, manufacturers can reduce waste and energy use, achieving more sustainable operations.

- Digital Twins: Incorporating Genomics of Industrial Processes into digital twins creates virtual representations of physical systems, enabling manufacturers to test scenarios and optimize processes before real-world implementation.

Conclusion

Genomics of Industrial Processes is redefining proactive quality control by focusing on real-time defect prevention and efficiency. Leveraging AI and ML, manufacturers can predict and intervene in potential defects before they occur, moving away from traditional reactive methods. The broader implications of Genomics of Industrial Processes across predictive maintenance, supply chains and sustainability highlight its transformative potential in achieving zero-defect manufacturing. As the manufacturing industry evolves, adopting methodologies like Genomics of Industrial Processes will be essential for staying competitive, optimising resources and embracing sustainability. Genomics of Industrial Processes is more than just a technological innovation – it’s a shift towards a future where processes are not just managed but perfected in real-time.

Read whitepaper – “Unlocking Zero-Defect Manufacturing with Genomics of Industrial Processes”