Our modern industrialism, changed to motives of public service,

will provide means to remove every injustice that gives soil for prejudice”

– Henry Ford, 1922

While the lofty claim by Henry Ford way back over 100 years ago that modern industrialism could solve society’s ills may not have come to pass, it is equally clear that people must remain at the heart of industrial production. However, as the advancements of Industry 4.0 brought automation, interconnectivity and smart technologies to the forefront, the concern has grown that the nature of work could change beyond recognition.

That is perhaps why we are now seeing the next revolution, Industry 5.0, begin to emerge. This new paradigm aims to bring a more human-centric approach to manufacturing, emphasising collaboration between humans and machines.

So what is Industry 5.0, what are its key components, and what might its potential impact be on the manufacturing sector?

What is Industry 5.0?

Industry 5.0 builds upon the foundations laid by Industry 4.0, which introduced the Internet of Things (IoT), big data analytics, and cyber-physical systems. While Industry 4.0 focuses on automation and efficiency, Industry 5.0 seeks to integrate human intelligence with machine capabilities, fostering a collaborative environment where humans and robots work side by side. This shift emphasises personalisation, customisation, and sustainability, ultimately aiming to enhance the quality of life and create more value for society.

Key Components of Industry 5.0

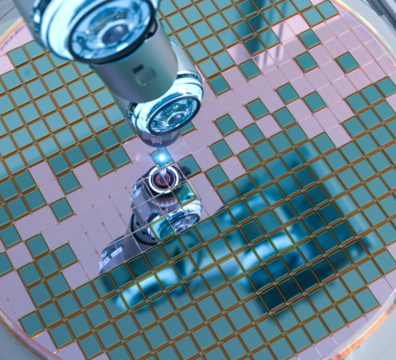

- Human-Robot Collaboration: At the core of Industry 5.0 is the collaboration between humans and robots. Unlike the fully automated systems of Industry 4.0, Industry 5.0 promotes the idea of humans and robots working together. Cobots, or collaborative robots, are designed to assist human workers, taking on repetitive or dangerous tasks while allowing humans to focus on more complex and creative aspects of production.

- Personalisation and Customisation: Industry 5.0 aims to meet the growing demand for personalised products. By combining human creativity with advanced manufacturing technologies, companies can offer customised solutions tailored to individual customer preferences. This approach not only enhances customer satisfaction but also opens new markets for unique and bespoke products.

- Sustainability and Ethical Manufacturing: Sustainability is a critical focus of Industry 5.0. This new industrial revolution emphasizes environmentally friendly practices and the ethical treatment of workers. Companies are encouraged to adopt green technologies, reduce waste, and implement circular economy principles. Additionally, the human-centric approach ensures that workers’ well-being and safety are prioritized.

- Advanced Technologies: Industry 5.0 leverages cutting-edge technologies such as artificial intelligence (AI), machine learning, and advanced robotics. These technologies enhance production processes by providing intelligent insights, predictive maintenance, and real-time decision-making capabilities. The integration of these technologies with human skills leads to more efficient and resilient manufacturing systems.

Impact on the Manufacturing Sector

This human-centric, sustainable approach to manufacturing has the potential to fundamentally transform both our relationship with technology and with work more generally.

- Increased Productivity and Efficiency: The collaboration between humans and machines in Industry 5.0 is expected to boost productivity. Cobots can handle mundane and physically demanding tasks, allowing human workers to engage in more value-added activities. This synergy can result in faster production times and higher overall efficiency.

- Enhanced Job Satisfaction: By automating repetitive tasks, Industry 5.0 will allow workers to focus on more engaging and intellectually stimulating activities. This shift can lead to higher job satisfaction and improved mental health among workers. The emphasis on ethical practices and worker safety further contributes to a positive work environment.

- Greater Innovation and Creativity: The human-centric approach of Industry 5.0 fosters an environment of innovation. Workers can leverage their creativity and problem-solving skills, supported by advanced technologies. This collaboration can drive the development of new products and processes, leading to a competitive edge in the market.

- Sustainable Growth: Industry 5.0’s focus on sustainability aligns with global efforts to combat climate change and promote responsible consumption. By adopting eco-friendly practices and reducing waste, companies can contribute to a healthier planet while also benefiting from cost savings and enhanced brand reputation.

Conclusion

Industry 5.0 represents a significant evolution in manufacturing, bringing together the best of human intelligence and machine efficiency. This new industrial era promises to create a more sustainable, personalised, and ethical approach to production, ultimately enhancing the quality of life for workers and consumers alike.

Where before the choice between operational efficiency and sustainability was seen as a black-and-white either/or choice, the application of advanced AI means the new ability to co-optimise both; An intelligent trade-off, where the business and society both win.